TUBE TURNS® Products manufactures all of its products at its facilities in Louisville, Kentucky, USA and Toluca, Mexico. The Louisville factory houses a 37,000 ft.2 (3,437 m2) manufacturing and assembly area and 11,000 ft2 (1,022 m2) of warehouse space. The facility has 10-ton hoist capacity.

Non-Destructive Examination Services

The Company offers a Non-Destructive Examination (NDE) services on-site at the Louisville facility under engineering department supervision while all exams are performed by a licensed Level II technician. Capabilities include X-ray, Ultrasound, Magnetic Particle (MP), Liquid Penetrant (LP), Hydrotest and Helium Leak Detection.

Quality Program and Certifications

TUBE TURNS® Products maintains a quality program per ASME, Section VIII, Division 1, Appendix IX, and is authorized by ASME and the National Board to use the U, R and NB stamps. The quality program is audited by third-party inspector, The Hartford Steam Boiler Inspection and Insurance Co. (HSB Global Standards, a subsidiary of Munich Re Group), and the State of Kentucky.

In addition TUBE TURNS® closure products have been awarded Canadian Registration Numbers (CRN) that are a requirement to provide pressure-retaining equipment to Canadian Provinces. The Company follows the latest industry standards and designs products to meet ASME B31.3, B31.4, B31.8, API, NACE and PED upon specification.

We also design couplings and closures per PVHO (Pressure Vessels for Human Occupancy) Code to meet our Commercial Diving customers' requirements. TUBE TURNS® Quality Management System is certified to ISO 9001:2015.

Manufacturing Capabilities

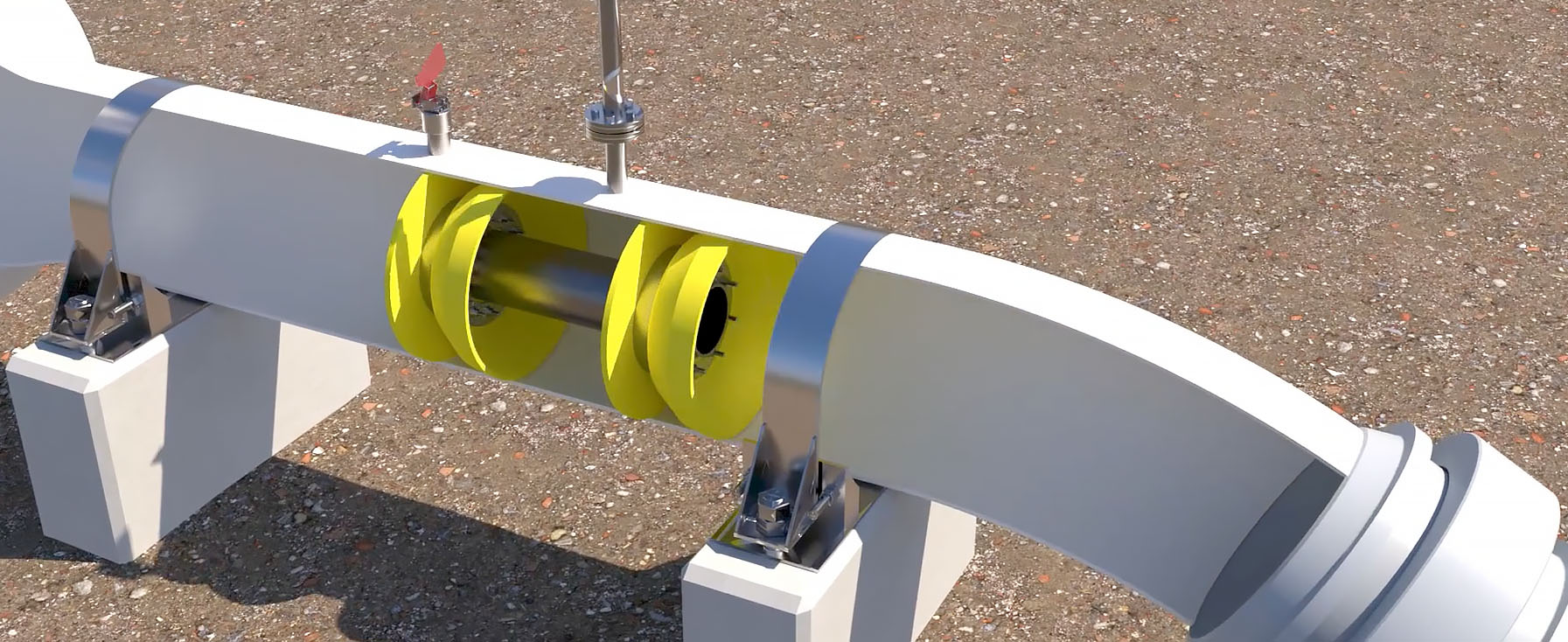

Since 1927, TUBE TURNS® Products has served the oil, gas, petrochemical, and process industries as a leading manufacturer and supplier of engineered specialty piping components and quick opening closures. Our facilities provide global reach to meet our customers' evolving demands with advanced engineering and manufacturing capabilities.

We specialize in high-pressure, high-temperature applications and continually invest in the latest design software, testing equipment, and manufacturing technologies to provide our customers with innovative solutions for their most challenging applications.

Industry Standards Compliance

Our products are designed and manufactured to meet the most stringent industry standards including:

- ASME Section VIII, Division 1

- ASME B31.3, B31.4, B31.8

- API Standards

- NACE Specifications

- PED (Pressure Equipment Directive)

- PVHO (Pressure Vessels for Human Occupancy) Code