Swel-Plug® Hydrostatic Tester

Faster, Easier and More Economical Pipeline Testing

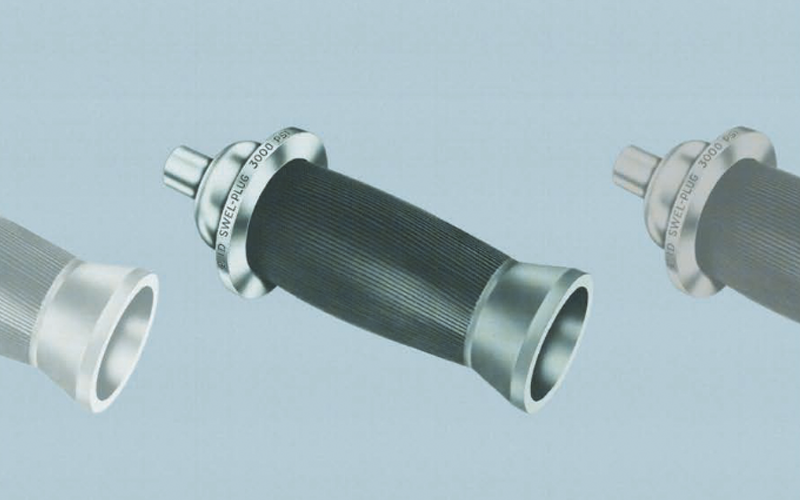

Rugged, positive-grip end closure that speeds up hydrostatic testing

Overview

TUBE TURNS® Swel-Plug® Pressure Tester is a rugged, positive-grip end closure that speeds up and simplifies hydrostatic testing of pipelines and piping assemblies. The Swel-Plug® was developed scientifically as a time and money saver.

Performance and dependability have been proven at numerous field installations and the Swel-Plug® Pressure Tester is being used more and more frequently by pipeline contractors, piping fabricators, mechanical contractors and maintenance departments.

Swel-Plugs® are perfect for steam cracker and PVC pipe applications, providing reliable sealing across a wide range of industrial requirements.

Key Features & Benefits

Six critical advantages that make Swel-Plug® the preferred choice for hydrostatic testing

Quick Installation & Removal

Can be installed or removed in minutes and reused repeatedly

Versatile Sizing

Each size handles a wide range of pipe IDs and wall thicknesses

Eliminates Welding Requirements

No need for welding caps, blind flanges, or plate blanks as end seals

No External Fixtures

Does not require elaborate fixturing or constant adjusting of clamps

Wide Pressure Range

Can be used with any test pressure from atmospheric to 3,000 psi

Proven Reliability

Performance and dependability proven at numerous field installations

Swel-Plug® vs Traditional Methods

See how Swel-Plug® eliminates the drawbacks of conventional testing methods

| Traditional Method | Swel-Plug® Solution | Benefit |

|---|---|---|

| Welding Caps | Quick mechanical installation | Saves hours of welding time |

| Blind Flanges | No bolt-up required | Eliminates flange preparation |

| Plate Blanks | Reusable design | Reduces material costs |

| External Clamps | Internal expansion | No external equipment needed |

Applications & Industries

Trusted by professionals across multiple industries for reliable testing solutions

Special Applications

Specialized solutions for demanding industrial environments

Steam Cracker Applications

Perfect for high-temperature petrochemical processing systems

Features:

- High-temperature compatibility

- Chemical resistance

- Reliable sealing

PVC Pipe Applications

Ideal for plastic piping system testing requirements

Features:

- Gentle sealing action

- No pipe damage

- Repeatable testing

Comprehensive Benefits

Three categories of advantages that deliver measurable value

Time Savings

- Minutes vs. hours for installation

- No welding or cutting required

- Immediate removal after testing

- No cool-down waiting time

Cost Reduction

- Eliminates consumable end caps

- Reduces labor requirements

- Reusable for multiple tests

- No material waste

Safety Benefits

- No hot work permits required

- Eliminates welding hazards

- Reduced fire risk

- Safer work environment

Technical Specifications

Key performance parameters for the Swel-Plug® Hydrostatic Tester

Pressure Range

Atmospheric to 3,000 psi

Installation Time

Minutes (both install and remove)

Reusability

Multiple uses without degradation

Grip Type

Positive-grip end closure

Pipe Compatibility

Wide range of IDs and wall thicknesses

Testing Method

Hydrostatic pressure testing

Need a Quote?

Let our experienced sales staff prepare a proposal for your requirements

Technical Literature

Download comprehensive documentation for Swel-Plug® Hydrostatic Tester

Related Products

Explore our complete range of specialized pipeline testing and connection solutions