Monolithic Insulated Joints

Electrically Isolate

Prevent corrosion caused by stray electrical currents and interference from other pipelines

Overview

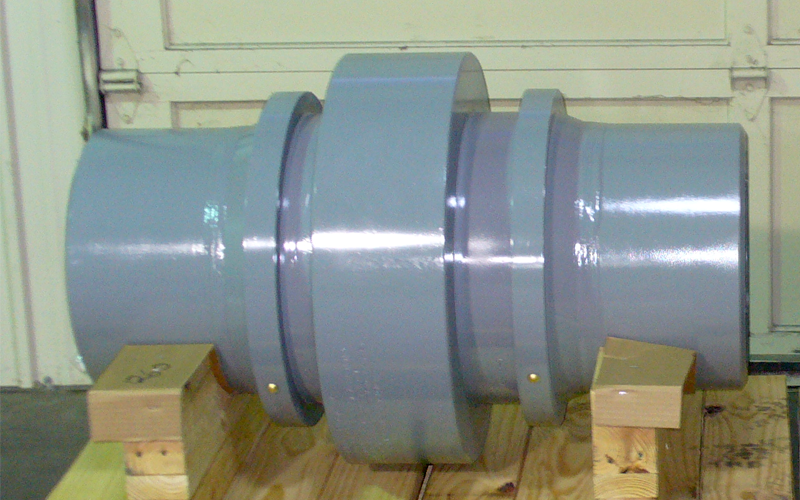

Insulated Joints (also referred to as "Isolation Joints" or "Insulating Joints") are available in sizes ranging from 2" through 48" and pressure ranging from ANSI 150 to ANSI 900.

TUBE TURNS® Monolithic Insulated Joints electrically isolate sections of pipeline to prevent corrosion caused by stray electrical currents or interference from other pipelines and power transmission cables.

The weld end hubs of our Insulating joints are provided in compliance with the customer's piping specification. Optional extra-length pipe pups (provided by the customer) can be included in the completed joint.

Technical Specifications

Comprehensive range of sizes and pressure ratings for various pipeline applications

Size Range

2" through 48" diameter

Pressure Range

ANSI 150 to ANSI 900

Design Type

Pre-fabricated, non-separable, bolt-less

Testing Pressure

1.5 times working pressure

Standards Compliance

Customer piping specifications

Maintenance

No maintenance required

Electrical Isolation Features

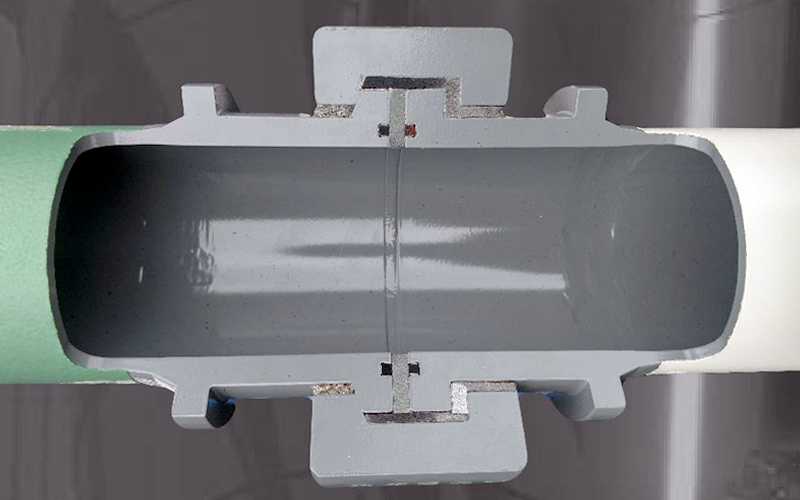

Three key features ensure complete electrical isolation across the joint

Insulating Gasket

Prevents metal-to-metal contact across the joint

Dielectric Compound

Internal cavities filled with special dielectric compound

Non-Conductive Coating

Two coats of non-conductive epoxy paint on internal and external surfaces

Design Advantages

TUBE TURNS® Monolithic Joints feature superior design for reliability and ease of installation

Single-Piece Construction

Simplicity of installation with no assembly required

Maintenance-Free

No maintenance required for entire service life

Superior Strength

Physically stronger than the pipe to which it is attached

Factory Tested

Hydrostatic and electrical testing before shipment

Monolithic Design

TUBE TURNS® Monolithic Joints feature a pre-fabricated, non-separable, and bolt-less design to satisfy customers that require a single-piece construction for simplicity of installation, elimination of maintenance, and ease of final wrapping and coating after installation in the pipeline.

Pressure Fatigue, Torsion and Bending proof testing of the design was carried out to provide a design that is physically stronger than the pipe to which it is attached.

Each joint manufactured by TUBE TURNS® is completely factory assembled and hydro-statically tested to 1.5 times the working pressure before shipment. In addition, each joint is electrically tested to verify its insulating capability.

Quality Assurance & Testing

TUBE TURNS® is fully qualified to provide comprehensive in-house testing and examination services

Applications

Critical protection for pipeline integrity and corrosion prevention

Industry Terminology

These connections are known in the pipeline industry by various terms:

Construction Details

Need a Quote?

Let our experienced sales staff prepare a proposal for your requirements

Technical Literature

Download comprehensive documentation for Monolithic Insulated Joints

Related Products

Explore our complete range of specialized pipeline solutions