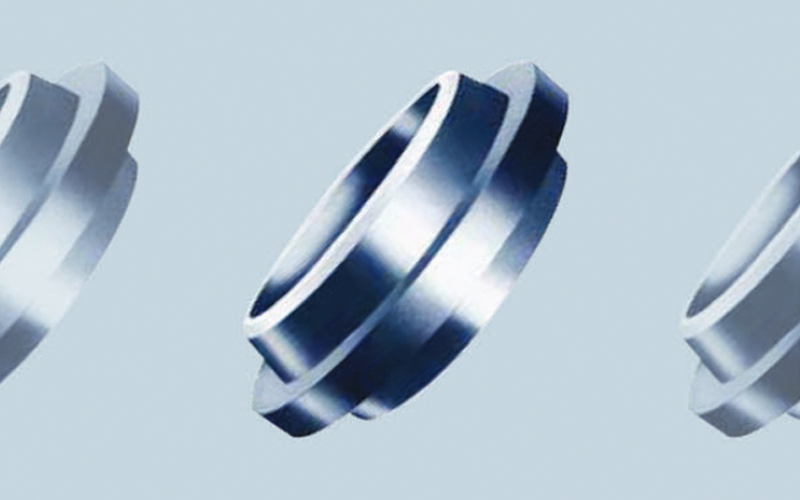

Anchor Forgings

Pipeline Immobilization Solutions

Custom engineered restraint systems for high pressure pipeline applications

Overview

Anchor Forgings, sometimes referred to as Anchor Flanges, are used for immobilizing high pressure pipe lines and restraining pipe movement where uncontrolled thrust load forces could damage equipment.

Anchor Forgings are custom designed to provide the most economical dimensions for each special application. Stress Calculations are provided as outlined in ASME Section VIII, Division 1, Appendix 2.

Our engineering team works closely with customers to ensure optimal design solutions that meet both performance requirements and cost objectives for critical pipeline restraint applications.

Key Applications

Essential solutions for pipeline safety and equipment protection

Design Considerations

Critical factors evaluated in every custom anchor forging design

Pipe Specifications

- Matching pipe O.D.

- Wall thickness requirements

- Minimum yield strength

- Material specification compliance

Operating Conditions

- Design pressure requirements

- Temperature differential considerations

- Environmental conditions

- Load factor specifications

Code Requirements

- Design Code (ASME, B31.4, B31.8)

- Design Factor specifications

- Design Concrete Bearing Stress

- Special application requirements

Industries Served

Trusted solutions across demanding industrial applications

Oil & Gas Pipelines

High-pressure transmission and distribution systems

Petrochemical Plants

Process piping with extreme pressure and temperature conditions

Power Generation

Steam and gas turbine piping systems requiring restraint

Chemical Processing

Corrosive and high-pressure chemical transfer systems

Technical Advantages

Engineering excellence that delivers superior performance and value

Custom Design Optimization

Each forging is engineered for maximum efficiency and cost-effectiveness

Benefits:

- Optimized material usage

- Reduced installation costs

- Enhanced structural integrity

- Application-specific geometry

Engineering Excellence

Complete stress analysis and calculation support

Benefits:

- ASME Section VIII compliance

- Detailed stress calculations

- Load distribution analysis

- Safety factor verification

Quality Assurance

Comprehensive testing and inspection protocols

Benefits:

- Material traceability

- Dimensional verification

- Non-destructive testing

- Certification documentation

Information Required for Quotation

To allow us to reply promptly to inquiries, please include the following information

Pipe Data

Matching pipe O.D., wall thickness, minimum yield, material specification

Design Conditions

Design Pressure

Thermal Conditions

Temperature Differential

Code Requirements

Design Code (ASME, B31.4, B31.8)

Design Parameters

Design Factor (if applicable)

Foundation

Design Concrete Bearing Stress

Application

Special Requirements

Our experienced engineering team will review your requirements and provide customized recommendations for optimal anchor forging solutions.

Technical Specifications

Key performance parameters for anchor forging design and manufacturing

Design Standard

ASME Section VIII, Division 1, Appendix 2

Construction Type

Custom forged design

Application

High pressure pipeline immobilization

Engineering Support

Complete stress analysis included

Design Codes

ASME, B31.4, B31.8 compliance

Customization

Application-specific geometry and dimensions

Need a Quote?

Let our experienced sales staff prepare a proposal for your requirements

Technical Literature

Download comprehensive documentation for Anchor Forgings

Related Products

Explore our complete range of specialized pipeline connection and support solutions