T-Bolt Closures

Nominal Pressure Applications

Economical, lightweight alternative to blind flanges for low to medium pressure

Overview

TUBE TURNS® exclusive T-Bolt Closure is designed expressly for low- to medium-pressure applications. It is lighter, less expensive and much more convenient than blind flanges and job-fabricated closure devices.

Economical price and low initial cost are especially attractive features of the TUBE TURNS® T-Bolt Closure. T-Bolt Closures are available in horizontal (opens like a car door) and vertical (opens like a car hood) configurations.

A complete unit normally costs less than the component parts for a blind or slip-on flange combination. There need be no additional expenses for hinges, hoists, davits, etc., as the closure can be fully assembled when shipped. Furthermore, installation-labor charges are held to a minimum; a single butt weld joins the closure to the vessel, vessel nozzle, or pipe.

Key Features & Benefits

T-Bolt closures engineered for economy, simplicity, and reliable operation

Economical Design

Lighter, less expensive and more convenient than blind flanges

Compact & Lightweight

Compact design with light weight for easy handling and installation

Quick Operation

Opens quickly and easily by loosening T-bolts until they clear holding lugs

Full Access

180° opening provides complete, unrestricted access

TOOL-LESS® Options

Breakover handles and camlock wrenches allow operation without tools

Safety Warning

Angled holding lugs provide pressure warning during opening

Design & Construction

Compact design, light weight, and simplicity of construction and operation

Construction Details

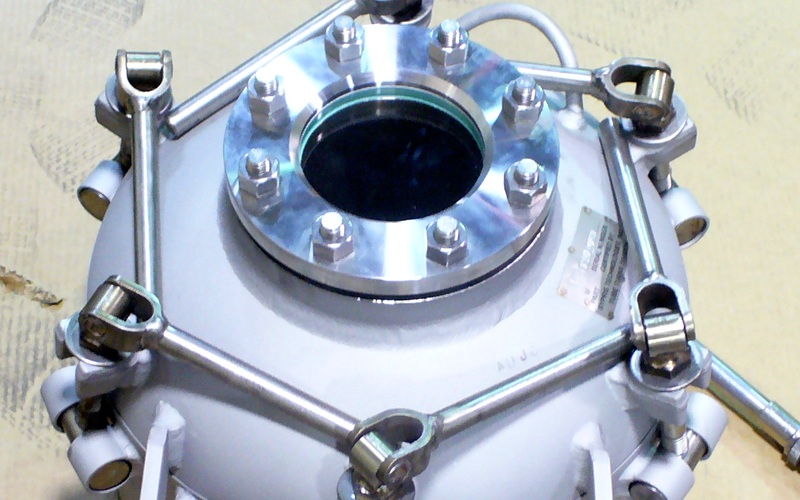

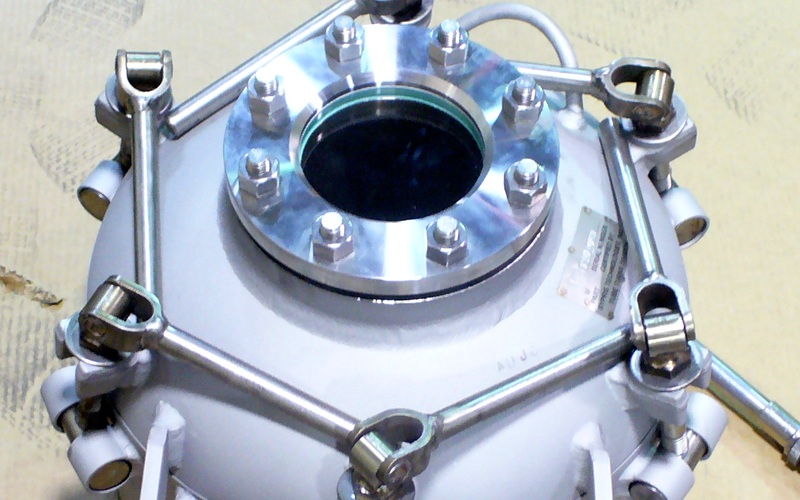

The closure consists of a thick elliptical head hinged to a matching hub, a self-energizing O-ring and a suitable number of T-bolts to effect and maintain a tight seal. For most services, the standard materials - carbon steel and a "Buna-N" O-ring - are satisfactory.

Configuration Options

Available in horizontal and vertical configurations to suit your application

Horizontal Configuration

Opens like a car door - ideal for side access applications

Vertical Configuration

Opens like a car hood - perfect for top access applications

Warning Features

Built-in safety features alert operators to potential pressure hazards

Angled Holding Lugs

Mounted at approximately 10° angle requiring extra turns to clear

Pressure Alert System

Initial turns allow head to lift slightly, releasing contained fluid

Controlled Opening

Head movement restrained until T-bolt clears holding lug completely

Operator Safety

Alerts operator to possible danger before full opening

The holding lugs are mounted on the closure head at an angle of approximately 10 degrees. This provides a valuable feature, for the angular mounting requires that the T-bolt be backed off an extra turn or two before it will swing out of the holding position. Thus, if there is pressure in the vessel while it is being opened, initial turns of the bolts permit the head to lift slightly and the contained fluid escapes, alerting the operator to possible danger. Further movement of the head is restrained, since the T-bolt still is confined within the holding lug.

Cost Advantages

Significant cost savings compared to traditional closure methods

Quick & Easy Operation

The T-Bolt Hinged Closure is opened quickly and easily. The operator merely loosens the T-Bolts until they clear the holding lugs and allow the head to be swung open on its hinge.

Complete, unrestricted access is provided; too, since the standard head stop permits a full 180° opening.

Other convenient options include breakover handles and camlock wrenches that allow the T-Bolt closure to be opened and sealed without tools.

ASME Code Stamped Closures

Code Stamping of TUBE TURNS® T-Bolt Closures is available on request at a nominal extra cost. This includes:

Applications

Ideal for low to medium pressure applications requiring frequent access

Materials Available

Gasket Materials

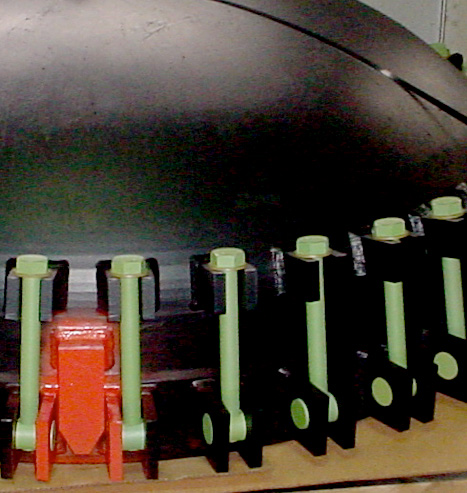

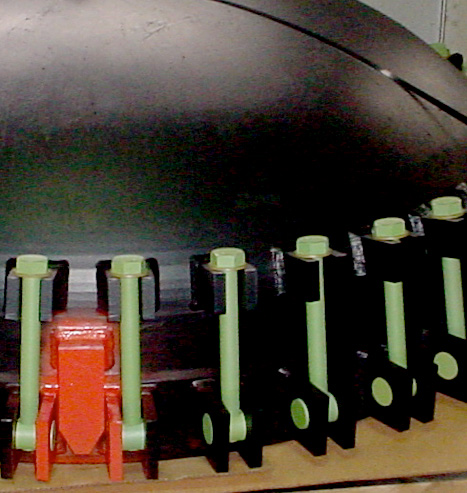

Product Gallery

T-Bolt closures in various configurations and applications

Literature & Documentation

Technical documentation and product information

T-Bolt Closure Brochure (EN)

PDF • English

T-Bolt Closure IOM TT710 (EN)

PDF • English

Related Products

Explore our complete family of quick opening closures

Need a Quote?

Let our experienced sales staff prepare a proposal for your requirements