Yoke Style Closures

Where frequent access is required

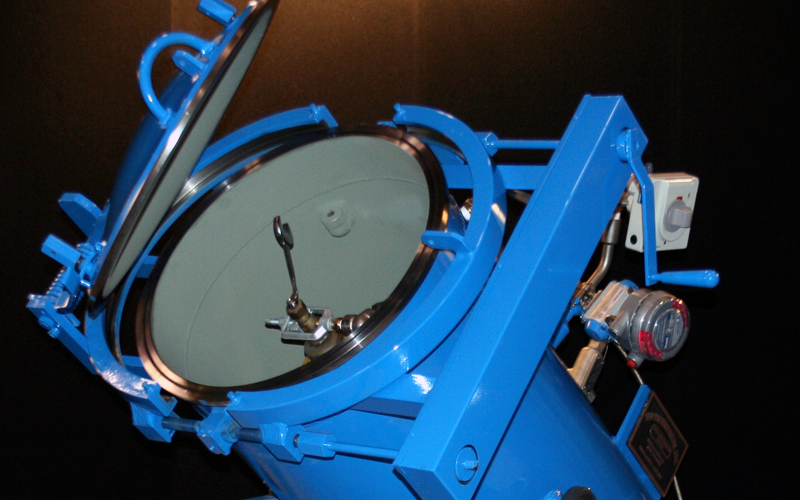

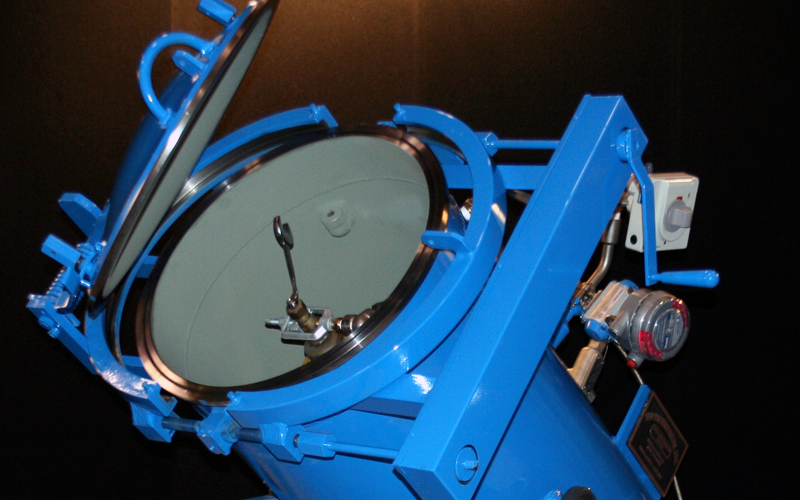

Manual Double-Bolt Yoke Style Closures

TUBE TURNS® Double Bolt Yoke style closure/manway is compact in size and functional in design. A typical unit consists of a forged hub, a hinged blanking head, split-yoke clamps, operating bolts, and a self-energizing O-ring gasket.

Materials of construction are in accord with ASME specifications, and manufacture complies with applicable rules of the applicable ASME code for Pressure Piping and with the ASME Boiler and Pressure Vessel Code.

Key Features & Benefits

Yoke Style closures engineered for reliability and ease of operation

Compact & Functional Design

Space-efficient design with forged hub and hinged blanking head

Self-Energizing O-Ring

Reliable sealing with self-energizing O-ring gasket system

Fast Operation

Opens/closes in minutes with standard hand tools

Split-Yoke Clamps

Dual actuating bolts spread yoke halves for easy access

ASME Code Compliance

Manufactured to ASME specifications with optional code stamping

Operating Aids Available

Chain & sprocket drives and other assistance options

Faster, Easier Operation

Operation is smooth and direct, and even the largest unit can be opened or closed in a matter of minutes. Turning of the actuating bolts - accomplished by one operator using only standard hand tools - spreads the yoke halves until they are fully separated, allowing the head to be swung open on its hinge.

There is no need to tug or hammer at dangerous or heavy flanges or metal doors or to struggle with bulky lugs and threads.

Chain & Sprocket Closures

The Chain and Sprocket Drive option is by far the most economical opening assist device we offer for the TUBE TURNS® Double-Bolt Yoke-style Closure. This is a manually operated aid which assists in the opening and closing of the yoke.

These units not only make the process faster, they also prevent uneven movement of the yokes which may cause binding. On larger closures, ratio reduction is available to further reduce the force required to operate the unit.

Design Details

Engineered sealing system with tapered contact surfaces

Contact surfaces of the clamping yokes, head and hub are tapered (at less than the friction angle) of dry carbon steel. When the head is closed and the yoke bolts are tightened, the head and hub are wedged together, compressing the O-ring and effecting a leak proof seal.

After the pipeline or vessel has been pressurized, the end load on the closure head intensifies frictional resistance at the tapered surfaces, thereby developing an inherent holding action that tends to overcome the relatively small component of force seeking to separate the holding elements. This design pre-supposes non-lubricated contact surfaces.

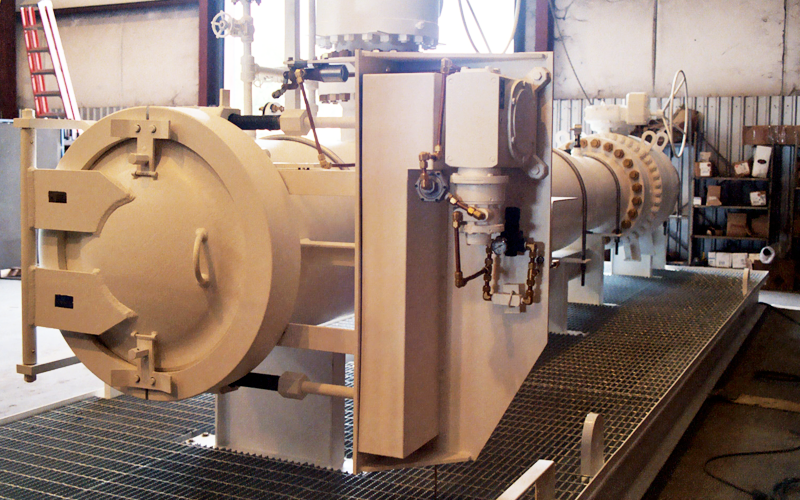

Technical Specifications

Available in a wide range of sizes and pressure ratings

Size Range

2" – 72" diameter

Pressure Range

ANSI 150 – ANSI 2500

Design Types

Double bolt and Single bolt configurations

Orientation

Horizontal and Vertical applications

ASME Code Stamped Closures

Code stamping of TUBE TURNS® Hinged Closures is available on request at a nominal extra cost. This includes:

Manufacturer's Statement of Code Compliance

In the event that shop inspection and stamping in accordance with Section VIII of the ASME Boiler and Pressure Vessel Code is not required, TUBE TURNS® can furnish a Manufacturer's Statement of Code Compliance.

This document affirms that the Hinged Closure is manufactured in accordance with the applicable requirements of the code.

Alternative to full ASME code stamping when not required

Applications

Ideal for applications where frequent access is required

Materials Available

Standards & Compliance

Product Gallery

Yoke Style closures in various configurations and applications

Literature & Documentation

Technical documentation available in multiple languages

Automated Yoke Style Closure (EN)

PDF • English

Yoke Style Closure Double Single Bolt Brochure (EN)

PDF • English

Yoke Style Closure IOM TT720 (EN)

PDF • English

Yoke Style Closure IOM TT1328 (ES)

PDF • Spanish

Yoke Overlay Mating Surfaces (EN)

PDF • English

Yoke Overlay Sealing Surfaces (EN)

PDF • English

Yoke Overlay Wetted Surfaces (EN)

PDF • English

Yoke Style Closure IOM (AR)

PDF • Arabic

Related Products

Explore our complete family of quick opening closures

Need a Quote?

Let our experienced sales staff prepare a proposal for your requirements